Prototyping Process

& 3D Printing Capabilities

What to Expect During the Prototyping Process

Prototyping isn’t about building a perfect version right away. It’s about learning what works, fixing what doesn’t, and making sure your final product is optimized for real-world use. Here’s what that process really looks like and what you should expect at each stage.

Stage 1: Discovery & Scoping

Together we can work to understand your functional requirements such as ON and OFF, linear, or momentary. Also determined is whether it needs to be wired or wireless and whether it is a brand-new build or something that can be adapted from an existing design. What is helpful at this stage: a wiring diagram, your basic specs, and a sense of what the final product needs to accomplish.

Some projects are scoped in a single call. Others take weeks or months. Either way, this phase sets the direction and helps both sides align before any design work begins.

Stage 2: Budgetary Quoting

Budgetary quoting is the fastest way to provide you with estimated pricing for a potential project using estimated volume. While not as detailed or accurate as a Production Release quote, this step helps gauge early interest and determine if the opportunity is worth pursuing further.

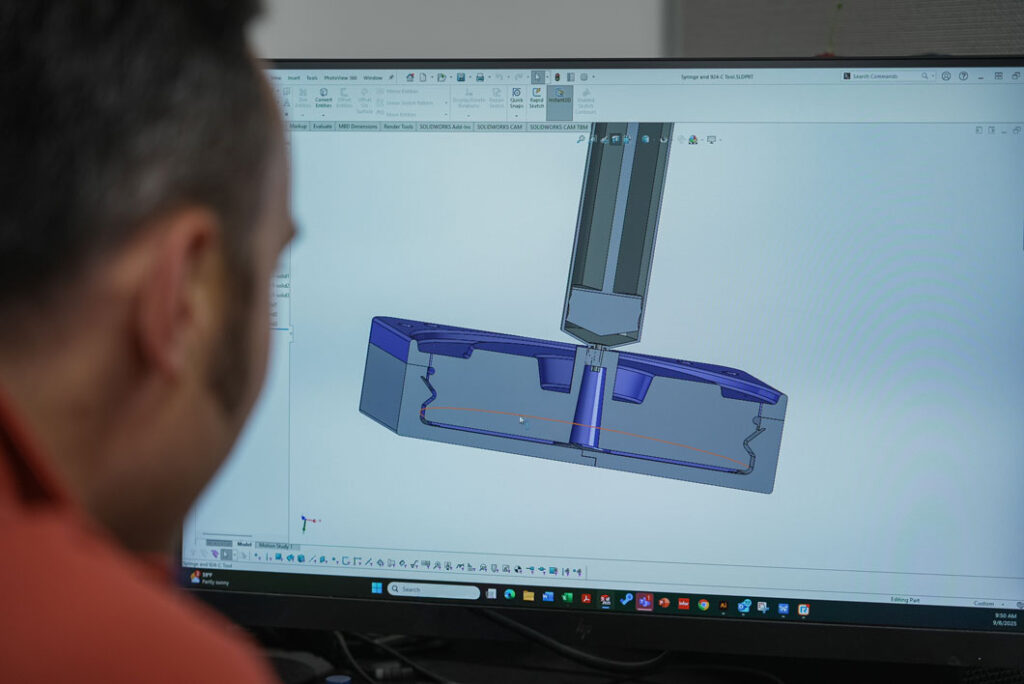

Rendering allows teams to visualize a switch digitally before committing to a physical prototype. Often completed during the budgetary quote phase, it is the first step in confirming overall shape, layout, and design direction before moving into printing or machining.

From your side, we’ll need decisions on:

• Estimated volumes used for pricing

• These quotes are approximate and may vary by ±5%

• Any final requirements that weren’t covered in the discovery phase

Important Notes:

• Orders cannot be accepted directly from a budgetary quote

• This is not a commitment to manufacture, but a way to see if the project is worth moving into prototyping or releasing into production

Renderings and budgetary quotes are usually delivered together, and any non-recurring engineering costs are clearly identified. This is when your budget really starts to come into focus and helps guide the project moving forward.

Stage 3: Prototype Design & Feasibility

This is where the idea starts to take shape. We get into CAD models, redline drawings, and part sourcing. Our job is to determine whether your concept is buildable and how to do it in a way that makes sense for your goals and budget.

From your side, we will need decisions on:

• How many units you will want for testing

• What kind of testing you plan to do

• Any must-haves like communication protocols, connectors to interface with your equipment, and LEDs to alert of different conditions

Stage 4: Building a Functional Prototype

Once the design is approved, and an order is received, we begin building. That includes ordering parts, finalizing the design, and starting any required firmware development. This is where communication matters most. You can determine LED behavior, pairing protocols, and button locations. Quick answers help keep everything on track. Delays at this stage usually come from missing information or slow feedback, not the actual build itself.

Cost at this stage depends on complexity. Wireless builds, custom tooling, or special materials will affect the price. Just to clarify, this is a functional prototype. It is not yet ready for regulatory approval.

Stage 5: Production Release

At this stage, you provide us feedback on changes required from the prototypes to make the design production ready. We will need your final documentation, including First Article Inspection quantities, test procedures, and operator instructions. From there, it is all about execution.

Production costs are quoted based on estimated volumes and V&V volumes. Component lead times and availability are dynamic, so the earlier you submit a PO, the smoother this phase will go.

Stage 6: V&V (Verification & Validation)

This is where you receive a product to be validated. You’ll receive a spec document to review and approve. From there, we produce a small batch of units for V&V and lock in any final changes based on results.

Most unexpected costs at this stage come from late adjustments, such as adding special packaging or requiring tooling or documentation that wasn’t discussed earlier. Having a clear approval process upfront helps minimize these surprises.

Once V&V is complete, the design is released to production for standard manufacturing.

What a Smooth Project Looks Like

One customer in the medical space came to us with everything clearly defined. They had a wiring diagram, selected a connector that was readily available, and were open to using stock parts where it made sense. They also requested one specific customization, a toe loop, which we integrated early.

Because they were clear, decisive, and collaborative, we hit every milestone and shipped early.

Common Mistakes and How to Avoid Them

A few things tend to trip up even well-planned projects:

- Not enough detail early on. Vague specs lead to vague quotes and missed expectations

- Changing scope midstream. Adding new features or materials late in the game slows everything down

- Slow communication. When responses lag, timelines get stretched. Weekly check-ins make a big difference

Our 3D Printing Capabilities

Seeing a design in physical form can shift the entire direction of a project fast. Drawings and models shape the early idea, but a printed part shows what the switch will actually feel like, how components fit together, and whether anything needs to be adjusted before moving further into development. That is where 3D printing has become one of the most useful tools in early foot switch design.

Types of Parts We Print

Right now, engineering is printing a wide range of components. One of the most common is microswitch and circuit board brackets. These are typically metal in final production, but printing allows engineering to quickly validate fit, alignment, and mounting geometry early in the design process before committing to tooling or machined parts.

- Wiring Channels

- Treadles

- Molds for Urethane Casting

Features such as mounting points, cable exits, pedal surfaces, and internal spacing all benefit from early prototype printing. Evaluating these areas helps gather feedback from manufacturing, marketing, sales, electrical engineering, mechanical engineering, and the customer.

Why 3D Printing Matters in Early Design

in early design, 3D printing is all about speed. it allows. engineers to quickly prototype parts to check fit, confirm dimensions, and validate core design concepts before committing to more time-consuming or expensive processes. Physical prints also reveal things CAD models cannot, like how parts flex, interact, and move in real world use. As a design progresses, prints can range from rough concept models to highly accurate parts used for detailed fit checks and customer evaluation. This early validation helps catch spacing and integration issues sooner, reducing the risk of costly changes later.

What the New Printer Improved

The newest printer expanded what engineering can evaluate in the early stages. It can print in different colors, which helps customers visualize how a switch will look with their system and supports their marketing teams during review. The surface finish is noticeably better too. Instead of visible layer lines, the print gives a smoother, more realistic preview of what the final molded part may look like.

Finer details stand out more clearly as well. Lettering and intricate surfaces print with higher definition, giving customers and engineers a more accurate physical reference before anything moves toward tooling.

Prototyping is not an extra step. It helps you avoid expensive problems later on. This is where problems get solved before you are dealing with delays, blown budgets, or parts that do not fit.