What Happens if You Push Power Through the Switch

Running high voltage or amperage straight through a foot switch can cause serious problems. When a switch is forced to handle more than it was designed for, the contacts inside can arc. Arcing happens when electricity jumps between the contacts as they open or close. This can burn or pit the contact surfaces, leading to poor conductivity and eventual failure.

As the contacts deteriorate, the internal mechanisms that keep the switch functioning smoothly can also be damaged. This kind of wear shortens the lifespan of the switch and increases the risk of it sticking, failing to activate, or breaking down completely.

Even if the switch does not fail right away, repeated exposure to these conditions puts constant stress on its internal components, making it less reliable over time.

How Foot Switches Are Rated

Every foot switch is tested and assigned a voltage and amperage rating based on what I it can safely handle. These ratings take into account this size of the contacts, how much current they can carry, how well they resist arcing, and how much heat the switch can dissipate during operation.

For example, a switch might be rated for a few amps at 125 volts or 250 volts. That does not mean it could safely handle more than that without consequences. If your system requires more than what the switch is rated for, you need another component to handle the load.

It is also important to understand that these ratings apply to resistive loads unless stated otherwise. When a foot switch is used directly with an inductive or capacitive load, such as a motor or transformer, those loads create extra electrical stress on the contacts. In these cases, it is common practice to de-rate the switch’s voltage and current capacity by about 50% to help prevent arcing and extend its lifespan.

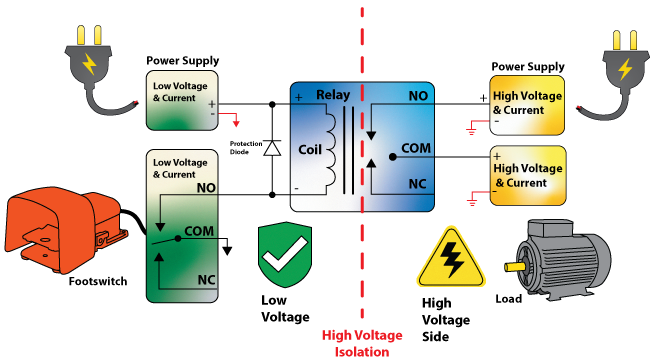

Why You Need a Relay

This is where a relay comes in. A relay isolates the foot switch from the heavy load. Instead of forcing the foot switch to carry high voltage or amperage, the switch only needs to send a small signal to the relay. The relay then uses its own contacts, which are designed to handle high power, to safely control the load.

By removing that stress from the foot switch, you prevent arcing, reduce contact wear, and keep the internal mechanisms of the switch from being overloaded. This approach protects the switch, extends its lifespan, and keeps the entire system operating safely.

Where This Applies

Relays are used in any situation where the power demand is greater than what a foot switch is rated to handle. That could be equipment with motors or any other setup where the current draw exceeds the limits of the switch. Adding a relay is not an extra feature. It is a standard practice to keep both the switch and the system running properly.

The Bottom Line

A foot switch is a control device, not a power device. Sending high voltage or amperage through it directly can lead to arcing, damaged contacts, and mechanical failures inside the switch. By using a relay, you keep the switch within its intended range, protect its internal components, and ensure long-term reliability.

If you are unsure whether your application requires a relay, start by checking the ratings on your foot switch and comparing them to what your system needs. If the two do not match, adding a relay is the right move.

Keep Learning

If you want to learn more about how to choose the right components for your setup, head to the Learning Center. You will find more blogs that break down electrical and mechanical concepts in simple terms so you can make better decisions for your equipment.

Date Uploaded 09/05/25

In collaboration with William Chan (Chief Electrical Design Engineer)

Custom Footswitches

Linemaster’s custom footswitches are designed to meet specific user requirements, offering a range of features such as various pedal configurations, wired and wireless options, and customizable LED indicators. These custom footswitches provide reliable, durable solutions tailored to enhance functionality in diverse applications.